Welcome to Standphill India

- CALL US: +91-9667674225

- Mail US : info@standphillindia.in

- Laxmi Nagar New Delhi

Table of contents

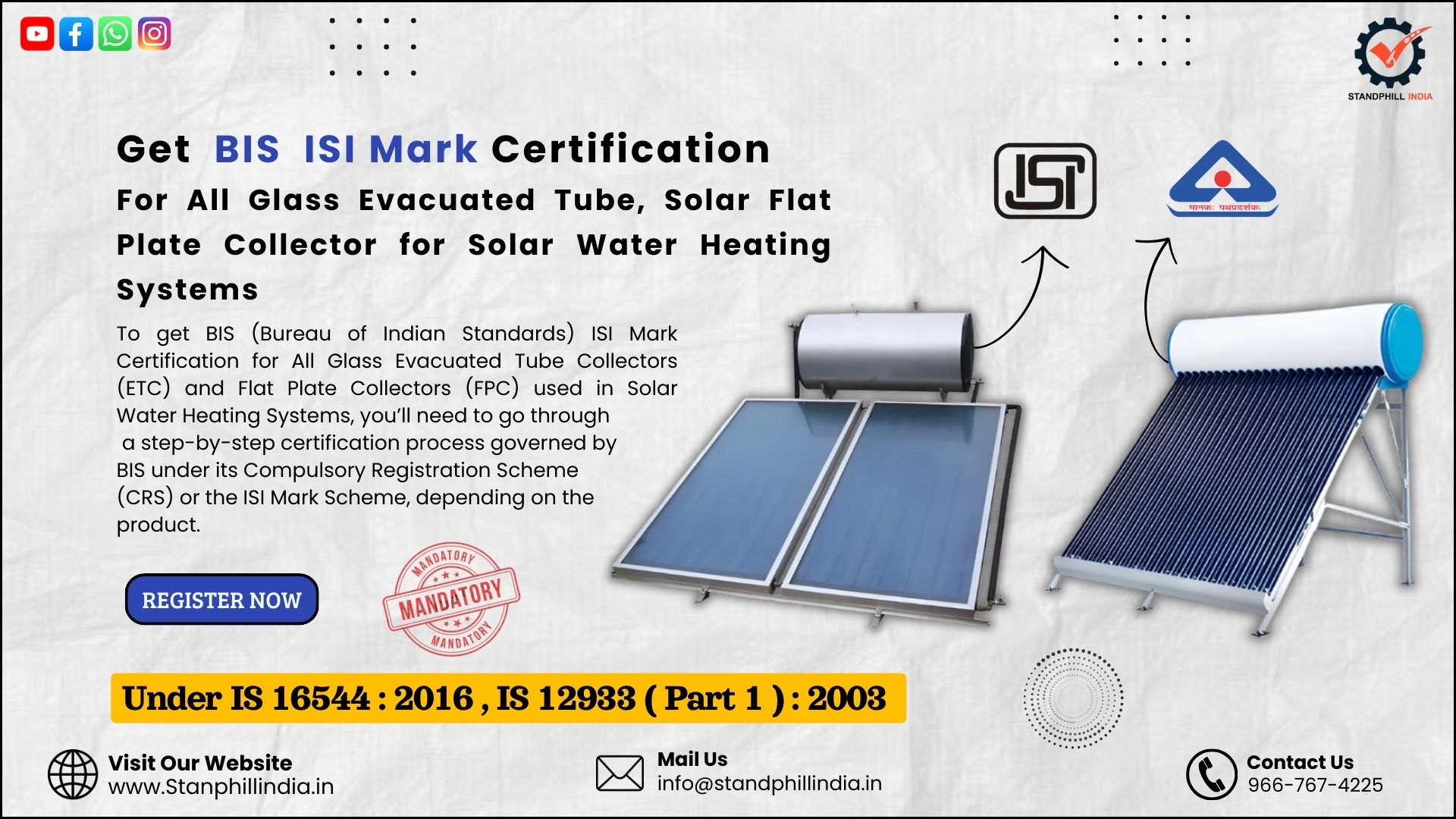

BIS Certification for Solar Water Heating Systems

Comprehensive Guide for Glass Evacuated Tubes and Flat Plate Collectors

India’s push toward clean and renewable energy has propelled the demand for solar water heating systems, which are now widely adopted in homes, industries, institutions, and commercial facilities. These systems play a vital role in reducing dependency on conventional fuels, lowering carbon emissions, and supporting the country’s sustainable energy goals.

Key components of these systems—Glass Evacuated Tubes (GET) and Solar Flat Plate Collectors (FPC)—are responsible for capturing solar energy and converting it into usable heat. Given their crucial role in system performance and safety, it is essential that these components conform to rigorous quality and performance standards.

To regulate and standardize their production, the Bureau of Indian Standards (BIS) has mandated ISI Mark certification for both components under specific Indian Standards through a Quality Control Order (QCO). From February 2024 onwards, no non-certified product can be manufactured, imported, or sold in the Indian market.

In this article, we explore everything you need to know about BIS certification for solar water heating components, applicable standards, the certification process, and how Standphill India can be your trusted partner in achieving full compliance.

Why BIS Certification Matters

BIS certification is a hallmark of quality, safety, and regulatory compliance. With solar energy systems becoming integral to India's infrastructure, quality assurance is critical. Defective or substandard components not only reduce energy efficiency but may also pose long-term safety risks and environmental concerns.

Key reasons why BIS certification is crucial:

Mandatory under Indian law for manufacturing and sale

Assures durability and thermal efficiency of solar components

Improves credibility and acceptance in both domestic and global markets

Enables participation in government tenders and subsidies

Protects consumers and boosts industry standards

Applicable Indian Standards for Certification

To ensure product reliability, the following Indian Standards (IS) apply to key solar water heating components:

Component IS Code Description

| Glass Evacuated Tube IS 16543 | Specifies quality and performance for double glass evacuated solar tubes |

| Flat Plate Collector IS 12933 (Part 1): 2003 | Defines materials, construction, performance, and safety standards for FPCs |

These standards include requirements for thermal performance, material strength, pressure tolerance, corrosion resistance, and environmental safety.

Quality Control Order – Government Regulation

The Department for Promotion of Industry and Internal Trade (DPIIT), under the Ministry of Commerce and Industry, has made it compulsory for manufacturers and importers to obtain BIS certification for these solar components.

Key Highlights of the QCO:

Certification under Scheme I of BIS Product Certification Scheme is mandatory.

Products must carry the ISI Mark with the applicable IS code.

Non-compliance will restrict market access, result in product recalls, and may incur legal penalties.

Both domestic and international manufacturers must obtain a valid BIS license to sell or supply in India.

Major Tests as per IS Standards

To receive BIS certification, products must pass a series of tests in BIS-recognized laboratories. These tests ensure that the components meet both structural and thermal performance standards.

Tests for Glass Evacuated Tubes (IS 16543):

Thermal Shock Test

Impact Resistance Test

Vacuum Retention Test

Transmittance and Emittance Testing

Coating Adhesion and Durability Tests

Tests for Flat Plate Collectors (IS 12933):

Thermal Performance Efficiency Test

Stagnation Temperature Test

Pressure Resistance Test

Rain Penetration Test

Absorber Coating Durability

Insulation Resistance Test

All components must comply with dimensional, material, and mechanical standards, including resistance to environmental stressors such as heat, humidity, and UV exposure.

BIS Certification Process – Step-by-Step

Achieving BIS certification involves several phases, including technical assessments and factory evaluations. The process must be conducted with precision and timely documentation.

Stepwise Process:

Application Submission:

Submit an online application through the BIS portal with details of the product, manufacturing unit, and supporting documents.

Sample Testing:

BIS selects product samples and sends them to BIS-approved laboratories for testing under the relevant IS code.

Factory Inspection:

BIS officers conduct on-site inspections to verify manufacturing processes, quality controls, and conformity to standards.

Evaluation & License Grant:

After successful test results and inspection clearance, BIS grants the license and authorizes use of the ISI mark.

Surveillance & Renewal:

BIS conducts periodic audits to ensure continued compliance. Licenses must be renewed as per BIS guidelines.

How Standphill India Supports You

Navigating the BIS certification process requires deep technical understanding, accurate documentation, and effective coordination with authorities. That’s where Standphill India comes in.

We provide full-service support to help manufacturers—both Indian and overseas—achieve BIS compliance with ease and confidence.

Our Services Include:

Regulatory Consultation:

Determine applicable IS standards and understand QCO implications.

Testing & Lab Coordination:

Handle the testing process with BIS-accredited labs, including pre-verification of samples.

Technical Documentation:

Prepare and review all required files, including product specifications, test reports, drawings, and quality plans.

Audit & Inspection Readiness:

Train and assist your team for BIS factory inspections and ensure your processes align with required standards.

End-to-End Project Management:

From application filing to license grant, we manage the entire workflow for a smooth and successful certification journey.

International Manufacturer Support:

Assist foreign companies in registering with BIS and setting up operations for legal sales in India.

Quick Reference Summary

Product Glass Evacuated Tubes, Solar Flat Plate Collectors

| Applicable Standards | IS 16543, IS 12933 (Part 1) |

| Certification Type BIS ISI Mark Certification | Scheme I, Schedule II |

| Authority | Bureau of Indian Standards (BIS) |

| Eligibility | Indian & Foreign Manufacturers selling in the Indian market |

| Marking Requirement | ISI Mark with standard number and license ID on each certified product |

Conclusion

With the increasing adoption of solar energy in India, compliance with BIS standards is not only a regulatory necessity but also a competitive advantage. Manufacturers of Glass Evacuated Tubes and Flat Plate Collectors must ensure their products meet Indian standards to participate legally and profitably in this growing market.

Standphill India is your trusted compliance partner, offering strategic guidance and hands-on support through every stage of the BIS certification journey. Whether you are launching a new product or entering the Indian market from overseas, we help you get certified faster, smarter, and with full confidence.

Contact us today to get started with BIS certification for your solar water heating components.

For More Blogs Click Here.

1. BIS Certification for Printers in India – Complete Process

2. Get BIS Certification For Block Boards IS 1659:2004

3. BIS Certification for Fire Extinguishers in India

Our Frequently Asked Questions

Request a call back.

For Business: For Business inquiry fill our short feedback form or you can also send us an email and we’ll get in touch shortly, or Toll Free Number +91 85279 30453.

Office Hours : 09:00 and 20:00 Mon to Sat, Sun - Closed