Welcome to Standphill India

- CALL US: +91-9667674225

- Mail US : info@standphillindia.in

- Laxmi Nagar New Delhi

Table of contents

BIS Certification for High Density Polyethylene Pipes for Potable Water Supplies (IS 4984)

High Density Polyethylene (HDPE) pipes have become the preferred choice for potable water distribution systems across India due to their exceptional durability, corrosion resistance, flexibility, and ease of installation. To ensure the safety and reliability of drinking water infrastructure, the Bureau of Indian Standards (BIS) mandates compliance with IS 4984 for HDPE pipes used in potable water supplies. This certification is crucial for manufacturers seeking to participate in government water projects, municipal tenders, and infrastructure developments where quality and safety are paramount.

For HDPE pipe manufacturers, obtaining BIS certification under IS 4984 is not merely a regulatory requirement—it's a mark of quality that builds trust with regulators, procurement agencies, engineers, and end-users. Standphill India, as an experienced BIS certification consultant, provides comprehensive guidance to streamline the approval process, reduce risks, and accelerate time-to-market for manufacturers.

What is IS 4984: Specification for HDPE Pipes for Potable Water Supplies?

IS 4984 establishes comprehensive requirements for HDPE pipes intended for drinking water distribution systems. The standard covers dimensional specifications, material properties, performance criteria, testing methodologies, and marking requirements to ensure that HDPE pipes deliver safe, reliable, and long-lasting service in potable water applications.

Scope and Coverage of IS 4984 Standard

The standard specifies requirements for:

• Raw material grade and quality specifications for PE-HD (Polyethylene High Density)

• Dimensional tolerances and classification by nominal size and SDR (Standard Dimension Ratio)

• Hydrostatic performance requirements including long-term strength and short-term pressure tests

• Mechanical properties including tensile strength, elongation at break, and impact resistance

• Thermal characteristics and environmental stress crack resistance

• Chemical safety requirements for potable water contact applications

• Requirements for fittings, joints, and connection systems

• Marking, packaging, and traceability protocols

Compliance with IS 4984 ensures that HDPE pipes are suitable for potable water transport and can withstand prescribed operating conditions throughout their designed service life.

Key Technical Requirements Under IS 4984

| Technical Parameter | Specific Requirements | Testing Method |

|---|---|---|

| Material Specification | PE-HD material of specified grade with documented supplier certificates | Material certification and traceability |

| Dimensional Accuracy | Outside diameter, wall thickness, and ovality within specified tolerances per nominal size/SDR | Dimensional measurement as per IS standards |

| Hydrostatic Performance | Short-term burst pressure and long-term hydrostatic strength (HDB) evaluations | Hydrostatic pressure testing |

| Mechanical Properties | Tensile strength, elongation at break, resistance to slow crack growth | Tensile testing and notch tensile testing |

| Impact Resistance | Drop/impact behavior at defined temperatures (0°C and 23°C) | Impact testing as per IS 4984 |

| Chemical Safety | Suitability for potable water (migration/contamination limits as per relevant guidelines) | Extractability and migration tests |

| Thermal Properties | Thermal stability and environmental stress crack resistance | Heat reversion test and environmental stress crack resistance test |

| Marking & Traceability | Manufacturer name, BIS standard number, size/SDR, material type, batch information | Visual inspection and verification |

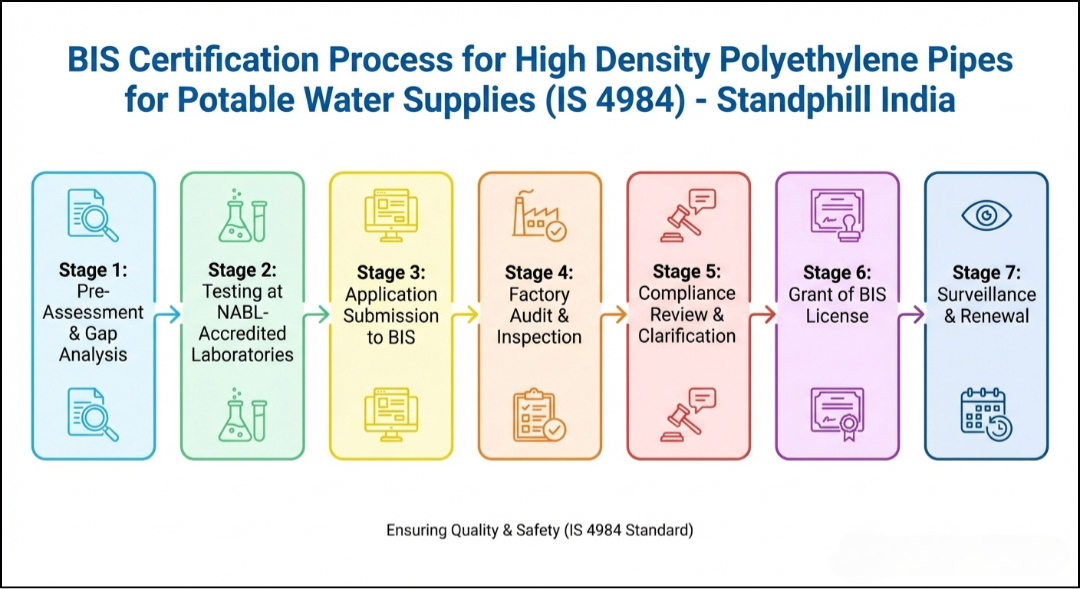

BIS Certification Process for HDPE Pipes Under IS 4984

The BIS certification process for HDPE pipes involves multiple stages that require careful planning, documentation, and coordination between manufacturing, quality assurance, and testing teams.

Stage 1: Pre-Assessment & Gap Analysis

Evaluate current product design, raw material certifications, in-house testing capabilities, and documentation against IS 4984 requirements. Identify gaps and develop a corrective action plan.

Stage 2: Testing at NABL-Accredited Laboratories

Arrange comprehensive product testing at BIS-recognized, NABL-accredited laboratories. Required tests include dimensional measurements, hydrostatic testing, tensile testing, impact resistance, and chemical safety evaluations.

Stage 3: Application Submission to BIS

Complete BIS application forms and submit with all required technical documents, test reports, quality manuals, and supporting documentation.

Stage 4: Factory Audit & Inspection

BIS officials conduct on-site factory inspection to verify production processes, quality control systems, testing facilities, record-keeping procedures, and traceability systems.

Stage 5: Compliance Review & Clarification

Address any non-conformities or queries raised by BIS during the review process. Submit corrective action plans and, if required, arrange for retesting of samples.

Stage 6: Grant of BIS License

Upon satisfactory compliance, BIS issues the Registration/License authorizing use of the ISI Mark for approved product scope.

Stage 7: Surveillance & Renewal

Periodic surveillance audits and sample testing ensure continued compliance. The license must be renewed as per BIS guidelines to maintain market authorization.

Documentation & Test Reports Checklist

| Document Category | Specific Documents Required |

|---|---|

| Application Documents | Completed BIS application forms, firm registration details, manufacturing license |

| Technical Specifications | Product drawings, technical specifications, standard operating procedures |

| Material Documentation | Raw material certificates, supplier declarations (grade, batch), material test certificates |

| Quality System Documents | Quality manual, internal QC procedures, calibration records for measuring instruments |

| Test Reports | NABL-accredited laboratory test reports for all required tests under IS 4984 |

| Traceability Records | Sample identification, batch traceability records, production batch records |

| Marking & Packaging Details | Marking specifications, packaging details, labeling requirements |

| Validation Records | Records of prior internal tests, validation trials, and quality audits |

Common Non-Conformities Manufacturers Should Avoid

Based on our experience with HDPE pipe certification, manufacturers frequently encounter these compliance challenges:

• Incomplete Test Reports: Submitting non-NABL or incomplete laboratory test reports

• Traceability Gaps: Lack of clear traceability between test samples and production batches

• Calibration Issues: Outdated or inadequate calibration certificates for testing equipment

• Documentation Deficiencies: Missing documented procedures for raw material handling and production controls

• Marking Non-Compliance: Improper product marking or packaging that doesn't meet standard requirements

• Material Certification Issues: Incomplete or non-compliant raw material certificates from suppliers

Why Choose Standphill India for HDPE Pipe BIS Certification?

Standphill India provides specialized, end-to-end BIS certification services tailored specifically for HDPE pipe manufacturers:

Comprehensive Gap Analysis: We conduct thorough pre-certification audits to map current practices against IS 4984 requirements and create prioritized corrective action plans.

NABL Laboratory Coordination: We identify appropriate accredited laboratories, manage sample submission, coordinate testing schedules, and provide technical interpretation of test reports.

Documentation Support: Our experts prepare complete application packages including quality manuals, SOPs, traceability templates, and technical documentation aligned with BIS expectations.

Factory Audit Preparation: We conduct mock audits, provide corrective action support, and prepare your team for successful BIS factory inspections.

Post-Certification Assistance: We offer ongoing support for surveillance audits, product scope expansions, compliance updates, and license renewals.

Technical Expertise: Our team includes materials engineers and piping specialists with deep understanding of HDPE technology and IS 4984 requirements.

"A leading HDPE pipe manufacturer reduced their certification timeline by 50% and achieved first-time approval with Standphill India's systematic approach to compliance and documentation."

Practical Tips for HDPE Pipe Manufacturers

Based on our experience facilitating numerous successful certifications, we recommend these best practices:

• Implement Document Control: Maintain a single-source document control system for all raw material and testing records

• Use Accredited Labs: Always use NABL-accredited laboratories for primary testing to avoid report rejections

• Maintain Calibration: Keep all calibration certificates current and readily accessible during audits

• Conduct In-House Testing: Implement comprehensive in-house acceptance testing to identify issues before official sampling

• Ensure Traceability: Establish robust traceability systems linking raw materials, production batches, and finished products

• Standardize Marking: Implement proper product marking and labeling procedures at the production line level

• Supplier Qualification: Develop strict supplier qualification criteria for raw material procurement

Conclusion: Secure Your Market Position with Quality Certification

Meeting IS 4984 requirements for HDPE pipes in potable water applications represents both a technical challenge and a significant market opportunity. As India continues to invest in water infrastructure through initiatives like Jal Jeevan Mission and AMRUT, certified products gain preferential access to government contracts and municipal projects.

Manufacturers who approach certification systematically—with validated test data, strict traceability systems, and robust quality management—not only secure approvals faster but also build stronger market credibility and customer trust. BIS certification under IS 4984 serves as a powerful differentiator in a competitive market, demonstrating commitment to quality, safety, and reliability.

Don't let certification complexities delay your participation in India's growing water infrastructure market. Partner with Standphill India to navigate the BIS certification process efficiently, ensuring your HDPE pipes meet all regulatory requirements while accelerating your access to lucrative government and municipal projects.

[ Schedule Your Free Pre-Assessment Today – Contact Standphill India ]

Our Frequently Asked Questions

While BIS certification may not be universally mandatory for all applications, most public water supply tenders, municipal projects, and government utilities require BIS certification or compliance with IS 4984 as a minimum qualification. Manufacturers should verify specific procurement requirements for their target markets.

Yes, BIS accepts test reports from NABL-accredited laboratories. Ensure the laboratory is accredited for the specific tests required under IS 4984 and that reports include complete sample details, traceability information, and proper signing authorities.

BIS typically issues an audit report detailing non-conformities and requests a corrective action plan with supporting evidence. Depending on severity, re-inspection or additional testing may be required. Timely, well-documented corrective actions minimize delays in certification.

Yes, we provide complete coordination services including sample collection, laboratory booking, test monitoring, and submission of required test reports to BIS as part of our comprehensive certification support package.

The complete certification process typically takes 8-12 weeks, depending on document readiness, testing schedules, factory audit availability, and BIS processing timelines. With proper preparation and expert guidance, this timeframe can often be optimized.

Request a call back.

For Business: For Business inquiry fill our short feedback form or you can also send us an email and we’ll get in touch shortly, or Toll Free Number +91 85279 30453.

Office Hours : 09:00 and 20:00 Mon to Sat, Sun - Closed